- AngularJS

- ReactJS

- Browserify

Cut-Off Discs

Metal Cut-Off Discs

It is suitable for ferrous metals, Unalloyed or low alloy steels, All kinds of rebar, Box profiles, Solid iron, Ç1040-1050 Steel flats, Steel construction, Welded manufacturing and Weld seam splitting operations. The product, which has aluminum oxide abrasive grains and a hard structure, has the advantage of long life and fast cutting.

T41 ,T42,

Metal Industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,

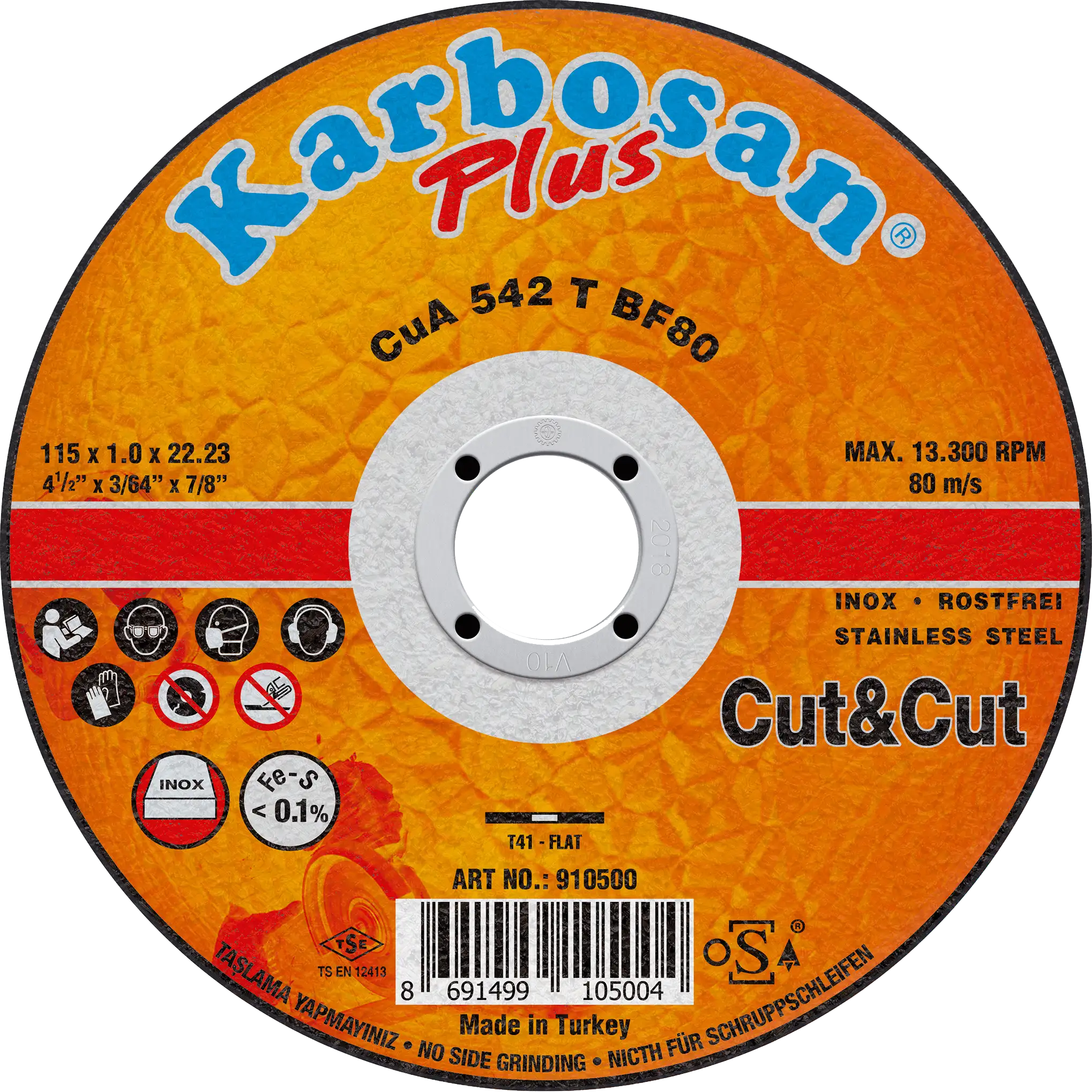

Stainless Steel (Inox) Cut-Off Discs

Suitable for cutting stainless steel (Inox), 304 and 316 L grade thin metal sheets, 304 grade stainless steel pipe, fl at bars. Featuring special aluminum oxide grains and a hard structure, the product minimizes the infl uence of heat on stainless materials, which demonstrate heat-sensitive behavior. The product does not contain iron (Fe) and sulfur (S).

T41 ,T42,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,

Aluminium Cut-Off Discs

Suitable for cutting operations on aluminium materials. Featuring aluminum oxide abrasive grains and a hard structure, the product is specially manufactured for cutting aluminium materials without clogging. Offers the advantage of convenient and fast cutting of aluminium materials.

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,

Zirconium Plus Thin Line Cut-Off Discs

Suitable for cutting stainless steel (Inox), 304 and 316 L grade thin metal sheets, 304 grade stainless steel pipe and fl at bars. Features special zirconium oxide and aluminum oxide abrasive grains and a hard structure. The product features a longer lifespan, advantage of faster cutting compared to its counterparts and has a specifi cation, which minimizes the heat effect on stainless materials that have sensitive nature against heat. The product does not contain iron (Fe) and sulfur (S).

T41 ,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,

Plus Thin Line Cut-Off Discs

Suitable for cutting stainless steel (Inox), 304 and 316 L grade thin metal sheets, 304 grade stainless steel pipe and flat bars. Features special aluminum oxide abrasive grains and a hard structure. Thank to its the speacial aluminum oxide abrasive grains, the product, features the advantage of faster cutting and minimizes the influence of heat on stainless materials, which demon-strate heat-sensitive behavior. The product does not contain iron (Fe) and sulfur (S).

T41 ,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels,

_1696250227.png)

Cast Iron Cut-Off Discs

Suitable for cutting processes of grey cast iron, sand fi nished surfaces, copper, brass, bronze, marble, artifi cial and natural rocks, asphalt, cement products and curbstones. Featuring silicon carbide abrasive grains and a hard structure, the product offers long lifespan for cutting processes of cast and non ferrous materials.

T41 ,T42,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,

Cut-Off Discs for Marble

Suitable for cutting artifi cial and natural rocks such as marble, brick, concrete, tile, shingle, curbstone. Featuring silicon carbide mixture abrasive grains and a hard structure, the product offers long lifespan and advantage of convenient cutting.

T41 ,T42,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,Metal Industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,Cast Steel ,Brass ,Stone,Glass,Granite,Artificial Rocks,Natural Rocks,Asphalt,Cement Products and Curbstones,

Industry Metal Plus Cut-Off Discs

Suitable for cutting process of nodular cast iron pieces, heat sensitive metals such as Ni-hard, all steels which are low alloy and with a hardness rating higher than 25 HRC. Featuring aluminum oxide abrasive grains and a hard structure, the product offers the advantage of fast and convenient cutting.

T41 ,T42,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,Cast Steel ,Brass ,Stone,Glass,Granite,Artificial Rocks,Natural Rocks,Asphalt,Cement Products and Curbstones,Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,

ZA Cast Iron Plus Cut-Off Discs

Suitable for cutting process of all nodular cast iron pieces, certain steel cast pieces, stainless steels and high alloy steels. Features zirconium oxide abrasive grains and a hard structure. Offers the advantage of extended lifespan since it can continue cutting without getting dull and offers higher stock removal in unit time.

T41 ,T42,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,Cast Steel ,Brass ,Stone,Glass,Granite,Artificial Rocks,Natural Rocks,Asphalt,Cement Products and Curbstones,Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,

AC Plus Cut-Off Discs for Cast Iron

Karbosan AC plus zirconium cast cutting discs contain a mixture of zirconium oxide and aluminum oxide abrasives.

They are generally used for pick cast, steel cast and nodular cast materials.

Karbosan AC plus cast cutting discs allow you to carry out cutting and grinding operations using a single disc which has a thickness of 3.8 mm.

They can be manufactured in larger diameters such as 400 or 500 mm. for suspended grinding machines.

T41 ,T42,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,Cast Steel ,Brass ,Stone,Glass,Granite,Artificial Rocks,Natural Rocks,Asphalt,Cement Products and Curbstones,Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,High Alloy Steels ,Steels,

Metal Stationary Machine Cut-Off Discs

They are suitable for cutting processes of structural steels (St37-42), rods and profiles. Featuring aluminum oxide abrasive grains and a hard structure, the product offers the advantage of fast cutting.

T41 ,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry , Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,Cast Steel ,Brass ,Stone,Glass,Granite,Artificial Rocks,Natural Rocks,Asphalt,Cement Products and Curbstones,Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,High Alloy Steels ,Steels,Low Alloyed Steels,Cast Steel ,High Alloy Steels ,Steels,

Cast Iron Stationary Machine Cut-Off Discs

Suitable for cutting process of spherical graphite cast iron (nodular casting), grey cast iron, aluminum, copper, brass, bronze etc. non ferrous metals. Featuring silicon carbide abrasive grains and a hard structure, the product offers long lifespan for cutting processes of cast and nonferrous materials.

T41 ,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry , Building Industry ,Machinery Industry,Metal Industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,Cast Steel ,Brass ,Stone,Glass,Granite,Artificial Rocks,Natural Rocks,Asphalt,Cement Products and Curbstones,Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,High Alloy Steels ,Steels,Low Alloyed Steels,Cast Steel ,High Alloy Steels ,Steels,Cast Steel ,Brass ,Steels,

Cast Iron Petrol Saw Cut-Off Discs

Featuring silicon carbide abrasive grains and a hard structure, the product offers long lifespan for cutting processes of asphalt, cement and curbstones.

T41 ,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry , Building Industry ,Machinery Industry,Metal Industry, Building Industry , Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,Cast Steel ,Brass ,Stone,Glass,Granite,Artificial Rocks,Natural Rocks,Asphalt,Cement Products and Curbstones,Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,High Alloy Steels ,Steels,Low Alloyed Steels,Cast Steel ,High Alloy Steels ,Steels,Cast Steel ,Brass ,Steels,Stone,

Metal Rail Cut-Off Discs

Suitable for all rail cutting processes. Featuring aluminum oxide abrasive grains and a hard structure, the product offers the advantage of cutting without run-out and vibration.

T41 ,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry , Building Industry ,Machinery Industry,Metal Industry, Building Industry , Building Industry ,Machinery Industry,Metal Industry,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,Cast Steel ,Brass ,Stone,Glass,Granite,Artificial Rocks,Natural Rocks,Asphalt,Cement Products and Curbstones,Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,High Alloy Steels ,Steels,Low Alloyed Steels,Cast Steel ,High Alloy Steels ,Steels,Cast Steel ,Brass ,Steels,Stone,Rail Steels ,Steels,

Zirconia Plus Rail Cut-Off Discs

Suitable for all rail cutting processes. Featuring special zirconium and aluminum oxide abrasive grains and a hard structure, the product offers the advantages of cutting without run-out and vibration, as well as high performance and fast cutting.

T41 ,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry , Building Industry ,Machinery Industry,Metal Industry, Building Industry , Building Industry ,Machinery Industry,Metal Industry,Metal Industry,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,Cast Steel ,Brass ,Stone,Glass,Granite,Artificial Rocks,Natural Rocks,Asphalt,Cement Products and Curbstones,Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,High Alloy Steels ,Steels,Low Alloyed Steels,Cast Steel ,High Alloy Steels ,Steels,Cast Steel ,Brass ,Steels,Stone,Rail Steels ,Steels,Rail Steels ,Steels,

Metal Cut-Off / Grinding Discs

Suitable for cutting and grinding processes of welding burrs, weld seams, all structural steels, low and high-alloy steels, hardened steels and common steel cast materials. Featuring aluminum oxide abrasive grains and a hard structure, the product offers the advantage of using a single product for both cutting and grinding operations.

T42,

Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Metal Industry,Machinery Industry,Metal Industry, Building Industry ,Metal Industry, Building Industry ,Plastic industry, Building Industry ,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry ,Machinery Industry,Metal Industry, Building Industry , Building Industry ,Machinery Industry,Metal Industry, Building Industry , Building Industry ,Machinery Industry,Metal Industry,Metal Industry,Shipbuilding Industry,Metal Industry,Automotive Industry, Building Industry ,

Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Stainless steel (Inox),High Alloy Steels ,Steels, Nonferrous Metals ,Cast Steel ,Brass ,Stone,Cast Steel ,Brass ,Stone,Glass,Granite,Artificial Rocks,Natural Rocks,Asphalt,Cement Products and Curbstones,Low Alloyed Steels,Cast Steel ,Welding ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,Stainless steel (Inox),High Alloy Steels ,Steels,Cast Steel ,High Alloy Steels ,Steels,Low Alloyed Steels,Cast Steel ,High Alloy Steels ,Steels,Cast Steel ,Brass ,Steels,Stone,Rail Steels ,Steels,Rail Steels ,Steels,Low Alloyed Steels,Cast Steel ,Welding ,High Alloy Steels ,Steels,

Cut Off Wheels are high-performance abrasive discs designed for cutting through a variety of materials, including metal, steel, stainless steel, aluminum, concrete, stone, and plastic. Commonly used in industrial fabrication, construction, metalworking, and automotive repair, these thin-profile wheels deliver clean, fast, and precise cuts with minimal material loss. Their slim design allows for reduced friction and heat buildup, making them ideal for applications that require accuracy, efficiency, and speed.

What Is a Cut Off Wheels?

A Cut Off Wheels is a reinforced abrasive disc engineered for straight cutting operations. Unlike grinding wheels, which are used for surface abrasion, cut off wheels are intended exclusively for separating materials. These wheels are typically used with angle grinders, stationary cut-off machines, or chop saws. They are composed of abrasive grains bonded with resin and often reinforced with fiberglass mesh to ensure strength and safety during high-speed rotations. Cut Off Wheels are essential for tasks where precision cuts and smooth edges are required, especially on metal and other dense materials.

Types of Cut Off Wheels

Cut Off Wheels come in various types depending on the material being cut and the machinery used:

Metal Cut Off Wheels: Designed for cutting ferrous metals such as steel, iron, and rebar. Available in general-purpose or specialized formulations for carbon steel and stainless steel (Inox).

Stainless Steel (Inox) Cut Off Wheels: Free from iron, sulfur, and chlorine, making them safe for corrosion-sensitive stainless steel cutting without contamination.

Aluminum Cut Off Wheels: Formulated to prevent clogging while cutting soft non-ferrous metals like aluminum and copper.

Masonry and Concrete Cut Off Wheels: Engineered to cut through brick, concrete, stone, and tile. Reinforced with durable bonds to withstand the abrasive nature of mineral-based materials.

Diamond Cut Off Wheels: Embedded with industrial-grade diamonds; ideal for hard materials such as ceramic, porcelain, stone, and reinforced concrete.

Thin Cut Off Wheels: Ultra-thin profiles for fast, clean, and burr-free cuts, often used in precision metalwork and auto body applications.

Applications of Cut Off Wheels

Cut Off Wheels are widely used across a range of industries and job types:

Metal Fabrication: Cutting pipes, rods, sheets, and structural components. Ideal for weld prep and precise part separation.

Automotive Repair & Manufacturing: Used for trimming panels, cutting bolts, removing exhaust parts, and preparing frames. Essential in bodywork and custom fabrication.

Construction: Cutting rebar, metal studs, concrete blocks, and masonry tiles on job sites with high precision and safety.

Industrial Maintenance: Ideal for plant maintenance and machinery servicing, where quick material separation is needed.

DIY and Home Renovation: Suitable for cutting metal frames, garden tools, tiles, and home improvement materials with compact angle grinders.

Key Features of Cut Off Wheels

High-Speed Performance: Designed for use with high-RPM power tools, offering rapid cutting with minimal effort.

Reinforced Safety: Fiberglass mesh layers provide structural integrity to prevent breakage during operation.

Thin and Precise: Narrow profiles ensure clean, straight cuts with reduced material loss and minimal burrs.

Material-Specific Formulations: Available for metal, stainless steel, aluminum, concrete, and stone.

Minimal Heat Buildup: Low friction design reduces heat generation, preventing material distortion and tool wear.

Long Service Life: Durable abrasive grains and strong bonding resins extend usability even in demanding conditions.

Low Vibration: Engineered to minimize vibration and enhance user comfort during prolonged use.

Environmentally Safer Options: Some formulations are free from iron, sulfur, and chlorine to avoid surface contamination, especially in stainless steel work.

Cut Off Wheel Prices

Cut Off Wheel pricing varies based on several key factors:

Diameter and Thickness: Larger and reinforced wheels are typically more expensive. Thin wheels for precision tasks are priced accordingly.

Abrasive Material: Aluminum oxide wheels are generally more affordable, while zirconia, ceramic, and diamond wheels come at a premium due to performance and longevity.

Application-Specific Use: Inox-safe or masonry-specific wheels may have specialized compositions that influence price.

Packaging: Wheels sold in bulk packs offer cost savings per unit compared to single purchases.

Brand Quality: Premium brands often offer enhanced durability, safety, and cutting speed, which reflects in their price point.

Choosing the right wheel for your application ensures cost efficiency, performance, and safety.

Karbosan Cut Off Wheels

Karbosan is one of Turkey’s leading abrasive product manufacturers, offering a broad range of high-performance Cut Off Wheels suitable for industrial, construction, and automotive applications. Established in 1967, Karbosan produces reliable, durable, and efficient cutting solutions tailored to meet the rigorous demands of professional users.

Karbosan Cut Off Wheels are manufactured using premium abrasive grains and reinforced fiberglass layers, ensuring long-lasting performance and operator safety. Whether you’re cutting stainless steel, mild steel, aluminum, or concrete, Karbosan provides optimized solutions for each material. Their Inox Cut Off Wheels are free from iron, sulfur, and chlorine—ideal for contamination-free stainless steel cutting.

In addition to excellent durability and high-speed performance, Karbosan products feature consistent cutting depth, minimal vibration, and improved operator control. Their wheels are available in a variety of diameters and thicknesses to suit different machinery and cutting requirements.

Karbosan continues to lead in innovation by combining international quality standards with environmentally friendly production methods and extensive technical support, making it a trusted brand in abrasive technology.

Veliköy OSB Sanayi Bulvarı No.: 76/A Çerkezköy / Tekirdağ - Türkiye

© Copyright 2000-2023 Karbosan. All rights reserved. MARK-A

Would you like to be our partner?

Would you like to be our partner?